-

Meqathatso ea Brass e Khethehileng e Phahameng ka ho Fetisisa

Kereiti:C21000, C22000, C23000, C24000, C26000, C26200, C26800, C27000, C27200, C28000 joalo-joalo.

Tlhaloso:Botenya 0.15-3.0mm, Bophara 10-1050mm.

Bohale:O, 1/4H, 1/2H, H, EH, SH

Tshebetso:Ho koba, ho tjheseletsa, ho qhibidiha, ho seha, ho phunya

Bokhoni:2000 Tons/ Kgwedi

-

Sesebelisoa sa koporo se sebetsang hantle bakeng sa cable

Sehlahisoa:lesela le hloekileng la koporo, lesela la koporo le se nang oksijene

Boitsebiso:Koporo ≥99.9%

Botenya:0.05mm-5mm

Bophara: 4-1000mm

Bokaholimo:bokahodimo bo benyang, bo hlwekileng ebile bo boreledi

-

Copper e hloekileng le copper alloy strip bakeng sa mochini o futhumatsang mocheso

Sehlahisoa:khoele e hloekileng ea koporo, khoele e se nang oksijene ea koporo, khoele ea koporo e nang le phosphorized, lesela la koporo, lesela la koporo la nickel alloy

Boitsebiso:Koporo e hloekileng 99,9%; Brass≥65%; Koporo nickel alloy≥70%

Botenya:0.05mm-5mm

Bophara: 4mm≤ x≤1000mm

Bokaholimo:bokahodimo bo benyang, bo hlwekileng ebile bo boreledi.

-

HVAC Copper pipe coil bakeng sa moea conditioner le sehatsetsi

Sehlahisoa:khoele e hloekileng ea koporo, khoele e se nang oksijene ea koporo, koporo e nang le phosphorized

Boitsebiso:Koporo ≥99.9%

Tlhaloso:

Ka ntle bophara: 3.18mm-28mm

Botenya ba lebota: 0.4-1.5mm

Bokaholimo:bokaholimo bo hloekileng le bo boreleli, ha bo na tšenyo

-

Bohloeki bo Phahameng Molemo ka ho Fetisisa Boleng ba Copper Strips

Kereiti:C11000, C12000, C12200, C10200, C10300 joalo-joalo.

Bohloeki:Cu≥99.9%

Tlhaloso:Botenya 0.15-3.0mm, Bophara 10-1050mm.

Bohale:O,1/4H, 1/2H, H

Lead time:Matsatsi a 10-30 ho ea ka bongata.

Tšebeletso:Ts'ebeletso e ikhethileng

Boema-kepe:Shanghai, China

-

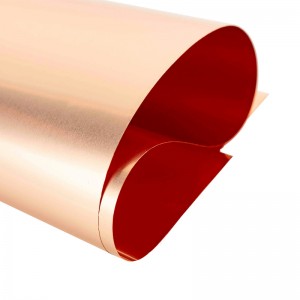

Fana ka foil ea koporo ea boleng bo holimo ea PCB ka litlhaloso tse fapaneng

Foil ea koporo ke thepa ea mantlha e sebelisoang ho PCB, e sebelisoang haholo ho fetisa mats'oao le mats'oao. Foil ea koporo ho PCB e ka boela ea sebelisoa e le sefofane sa litšupiso ho laola tšitiso ea mohala oa phetisetso, kapa joalo ka lera le sireletsang ho hatella tšitiso ea motlakase. Nakong ea ts'ebetso ea tlhahiso ea PCB, matla a ho ebola, ts'ebetso ea etching le litšobotsi tse ling tsa foil ea koporo le tsona li tla ama boleng le ts'epahalo ea tlhahiso ea PCB.

-

Iketsetse Foil ea Koporo e nepahetseng e phahameng

Sehlahisoa:Electrolytic koporo foil, Rolled koporo foil , Battery koporo foil, Plated koporo foil.

lintho tse bonahalang: Copper nickel, Beryllium koporo, Bronze, Koporo e hloekileng, Copper zinki alloy joalo-joalo.

Tlhaloso:Botenya 0.007-0.15mm, Bophara 10-1200 limilimithara.

Bohale:Annealed, 1/4H, 1/2H, 3/4H, Ho thata ka ho feletseng, Selemo.

Qetella:Bare, Tin plated, Nickel plated.

Tšebeletso:Tšebeletso e ikhethileng.

Boema-kepe:Shanghai, China.

-

Litheko tsa Fektheri li Fana ka boleng bo phahameng ba Copper Plate Copper Sheet

Sehlopha sa Alloy:C11000, C12000, C12200, C10200, C10300 joalo-joalo.

Bohloeki:Ke≥99.9%.

Tlhaloso:Botenya 0.15-80mm, Bophara≤3000mm, Length≤6000mm.

Bohale:O, 1/4H, 1/2H, H.

Lead time:Matsatsi a 10-30 ho ea ka bongata.

Tšebeletso:Tšebeletso e ikhethileng.

Boema-kepe:Shanghai, China.

-

Ts'ebetso e Phahameng ea Lithium Battery Copper Foil

Sehlahisoa:Lesela la koporo la electrolytic, foil ea koporo e kentsoeng, foil ea koporo ea betri,

Boitsebiso:Electrolytic koporo, bohloeki ≥99.9%

Botenya:6μm,8μm,9μm,12μm,15μm,18μm,20μm,25μm,30μm,35μm

Width: boholo ba 1350mm, iketsetse ka bophara bo fapaneng.

Bokaholimo:mathe a mahlakore a mabedi a benyang, a mahlakoreng a le mong kapa a boholo bo habeli.

Ho paka:sephutheloana se tloaelehileng sa ho romela thepa ka har'a mokotla o matla oa plywood.

-

Meqathatso ea Koporo ea Foil Bakeng sa Transformer

Transformer koporo foil ke mofuta oa khoele ea koporo e sebelisoang ho fehla moea ka lebaka la ts'ebetso ea eona e ntle le boiketlo ba ts'ebeliso. Koporo foil bakeng sa transformer matsoelintsoeke e fumaneha ka botenya tse fapa-fapaneng, bophara, le diameters ka hare, 'me e fumaneha hape ka foromo laminated le lisebelisoa tse ling.

-

Radiator e sebetsang ka ho Fetisisa ea Copper Foil Strip

Radiator copper strip ke thepa e sebelisoang litšeng tsa mocheso, hangata e entsoe ka koporo e hloekileng. Mochine oa koporo oa radiator o na le conductivity e ntle ea mocheso le motlakase oa motlakase, o ka tsamaisang mocheso o hlahisoang ka hare ho radiator ho ea tikolohong e ka ntle, kahoo o fokotsa mocheso oa radiator.

-

Wholesale Flexible Copper Braided Wires

Boitsebiso:Cu-ETP/C11000.

MOQ:Ha ho MOQ bakeng sa mefuta e tloaelehileng.

Tekanyo e tloaelehileng ea terata:0.2mm,0.15mm,0.127mm,0.12mm,0.1mm,0.07mm,0.05mm.

Nominal cross section:bonyane 1.5mm², boholo ba 120mm².

Kalafo ea Bokaholimo:Silver Plated, Nickel Plated, Tin Plated.

Lead time:Matsatsi a 3-15 ho ea ka bongata.

Tšebeletso:Tšebeletso e le 'ngoe ea OEM & ODM.

Boema-kepe:Shanghai, China.

- English

- Chinese

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Irish

- Greek

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

- Kinyarwanda

- Tatar

- Oriya

- Turkmen

- Uyghur