Foil ea koporoke thepa e hlokahalang tlhahisong ea boto ea potoloho hobane e na le mesebetsi e mengata joalo ka khokahano, conductivity, dissipation ea mocheso, le tšireletso ea motlakase. Bohlokoa ba eona bo iponahatsa. Kajeno ke tla u hlalosetsa kafoil ea koporo e kentsoeng(RA) le Phapang pakeng tsaelectrolytic koporo foil(ED) le ho hlophisoa ha foil ea koporo ea PCB.

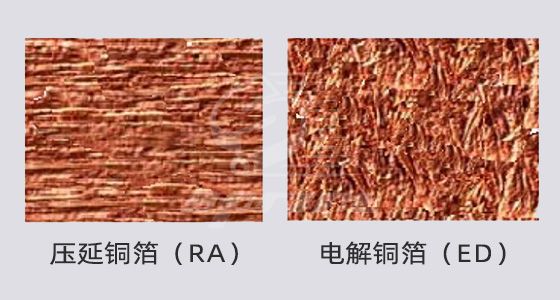

PCB foil koporoke thepa ea conductive e sebelisetsoang ho hokahanya likarolo tsa elektronike holim'a liboto tsa potoloho. Ho latela ts'ebetso ea tlhahiso le ts'ebetso, foil ea koporo ea PCB e ka aroloa ka mekhahlelo e 'meli: foil ea koporo e kolobisitsoeng (RA) le foil ea koporo ea electrolytic (ED).

Foil ea koporo e phuthetsoeng e entsoe ka likheo tse hloekileng tsa koporo ka ho bilika ho sa khaotseng le ho hatella. E na le bokaholimo bo boreleli, bokhopo bo tlase le conductivity e ntle ea motlakase, 'me e loketse phetiso ea mats'oao a maqhubu a phahameng. Leha ho le joalo, litšenyehelo tsa foil ea koporo e pota-potiloeng li phahame 'me boholo ba botenya bo lekanyelitsoe, hangata bo pakeng tsa 9-105 µm.

Electrolytic koporo foil e fumanoa ka electrolytic deposition processing holim'a poleiti ea koporo. Lehlakore le leng le boreledi mme le leng le kgohlahetse. Lehlakore le mahoashe le kopantsoe le substrate, ha lehlakoreng le boreleli le sebelisoa bakeng sa electroplating kapa etching. Melemo ea foil ea koporo ea electrolytic ke theko ea eona e tlase le mefuta e mengata ea botenya, hangata e pakeng tsa 5-400 µm. Leha ho le joalo, bokaholimo ba eona bo holimo 'me motlakase oa eona o fokola, o etsa hore e se ke ea tšoaneleha bakeng sa phetisetso ea maqhubu a phahameng.

Classification ea PCB koporo foil

Ho phaella moo, ho ea ka bokhabane ba foil ea koporo ea electrolytic, e ka aroloa ka ho eketsehileng ka mefuta e latelang:

HTE(High Temperature Elongation): Foil ya koporo e nang le mocheso o phahameng, e sebediswang haholo ka diboto tse ngata tsa mekgahlelo, e na le ductility e ntle ya mocheso o phahameng le matla a tlamahano, mme ho kgohlahala ka kakaretso ho pakeng tsa 4-8 µm.

RTF(Reverse Treat Foil): Khutlela morao tšoara foil ea koporo, ka ho eketsa lesela le itseng la resin lehlakoreng le boreleli la mochini oa koporo oa electrolytic ho ntlafatsa ts'ebetso ea sekhomaretsi le ho fokotsa ho ba thata. Bokhopo hangata bo pakeng tsa 2-4 µm.

ULP(Ultra Low Profile): Foil ea koporo e tlase-tlase, e entsoeng ka mokhoa o khethehileng oa electrolytic, e na le mahlahahlaha a tlaase haholo 'me e loketse phetisetso ea matšoao a lebelo le phahameng. Bokhopo hangata bo pakeng tsa 1-2 µm.

HVLP(High Velocity Low Profile): Foil ea koporo e phahameng ka lebelo le tlaase. E ipapisitse le ULP, e etsoa ka ho eketsa lebelo la electrolysis. E na le bokhopo bo tlase le bokhabane bo phahameng ba tlhahiso. Bokhopo hangata bo pakeng tsa 0.5-1 µm. .

Nako ea poso: May-24-2024